As Hudson’s Bay shutters the majority of its department stores across Canada, hundreds of local suppliers are left scrambling to reroute inventory and secure alternative retail partners—before time, space, and cash run out.

Montreal-based bedding company SmartSilk is among those caught in the retail fallout. Founder Yair Altman describes the situation bluntly: “We now have more product than shelf space. That means warehousing costs, logistical hurdles, and a race to find new homes for merchandise already en route.”

SmartSilk has been a long-time supplier to Hudson’s Bay, but with the company reducing its retail footprint to just six stores by mid-June, Altman and countless others are facing a commercial bottleneck.

“It’s not just us,” he said. “There are likely thousands of suppliers who now need to pivot, and quickly.”

A Shrinking Market for Leftover Stock

The closure of Bay stores and its luxury offshoot Saks comes in the wake of their parent company filing for creditor protection last month. The ripple effects have reached deep into Canada’s retail supply chain.

Retail alternatives are limited. Department stores are a dying breed, and those still operating—like Simons and Holt Renfrew—either focus on private labels or maintain an upscale brand curation incompatible with many Hudson’s Bay products. As Altman notes, “The only big volume players left are Walmart and TJ Maxx. But they demand deep discounts—something most of us can’t afford.”

For brands selling products with standard retail prices of $10, those discount retailers might only offer $5 or $6—barely covering production, let alone profit.

Emergency Plans and Inventory on the Ocean

For SmartSilk, existing partnerships with retailers like Costco provide some relief, but the challenge remains time-sensitive. With new shipments already ordered months in advance for spring and summer, delays can quickly turn into cash flow nightmares.

“If a product sits in a warehouse, it loses value every single day,” said Michelle Watson, founder of activewear brand Michi, who has experienced similar upheavals in past retail shakeups. “The longer we wait, the closer we get to forced markdowns and sunk costs.”

Altman explains that once goods are produced, there’s limited flexibility. “We can ask a factory to delay a shipment by two weeks, maybe three. Beyond that, it hurts their operations too. We’re all financially intertwined.”

Some companies are even resorting to more desperate tactics: leaving containers at sea to delay import costs. Mike Purkis, president of Caulfeild Apparel Group (maker of Joe Boxer), says he’s already been contacted by businesses in a panic.

“One brand had nine containers on the water and didn’t know what to do with them,” Purkis said. “That’s a huge risk. If they don’t find new retail channels, that inventory is deadweight.”

And even pausing at ports isn’t cheap—SmartSilk estimates it could cost $300 per day per container to hold stock at the docks.

Not All Are Caught Off Guard

Some companies, like Canadian Down and Feather, had seen the warning signs. “We noticed the late payments early on,” said CEO Ashwin Aggarwal, “so we limited our exposure and started looking for new partners.”

The Toronto-based pillow manufacturer is now targeting retailers like Sleep Country, Simons, and Linen Chest to diversify its sales portfolio.

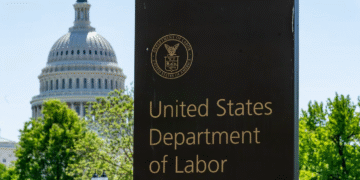

Others weren’t as prepared. Many relied solely on Hudson’s Bay and now face the steep uphill task of breaking into new markets, including the U.S.—a market that brings its own barriers, from tariffs to distribution hurdles.

A Wake-Up Call for Small Business

Supply chain expert Mike Croza, founder of the Supply Chain Alliance, says the situation highlights just how vulnerable small- and mid-sized Canadian businesses are when a major sales channel collapses.

“I feel for these companies,” Croza said. “They often lack the internal capabilities and foresight to manage such rapid disruptions. And now, they’re staring down serious financial strain.”

Altman agrees. “Some of my peers have told me they’re not sleeping at night. For a business with thin margins and tight cash flow, this isn’t just inconvenient—it’s existential.”

As the clock ticks toward mid-June, the fate of many Canadian brands hangs in the balance—stacked high on warehouse shelves, floating offshore, or awaiting a new retail lifeline that may never come.

English

English